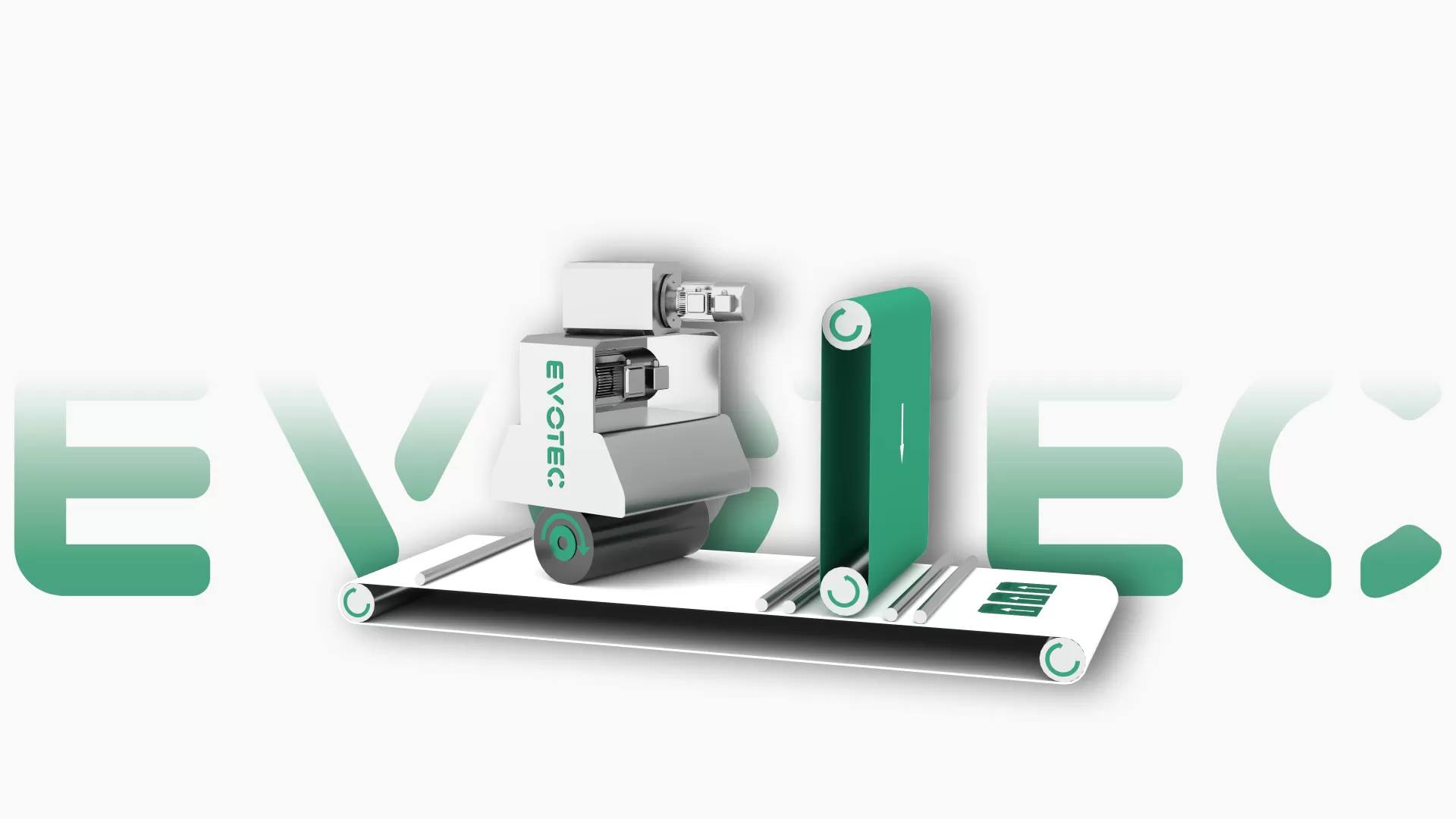

SR 300 – Precision Finishing for Small Parts

The SR 300 is a two-station finishing machine designed for safe, efficient processing of small components. Its magnet or vacuum system securely holds parts, while the automatically adjustable grinding unit prevents scratches when inactive.

With electrical compensation on the brush units, the conveyor belt is protected from wear, and the intuitive touchscreen allows easy speed adjustments for the belt, brushes, and grinding unit. Automated programs enable effortless repetition, with optional brush calibration for added precision. Fully automated stations ensure optimal performance and a seamless user experience.

Workstation Display

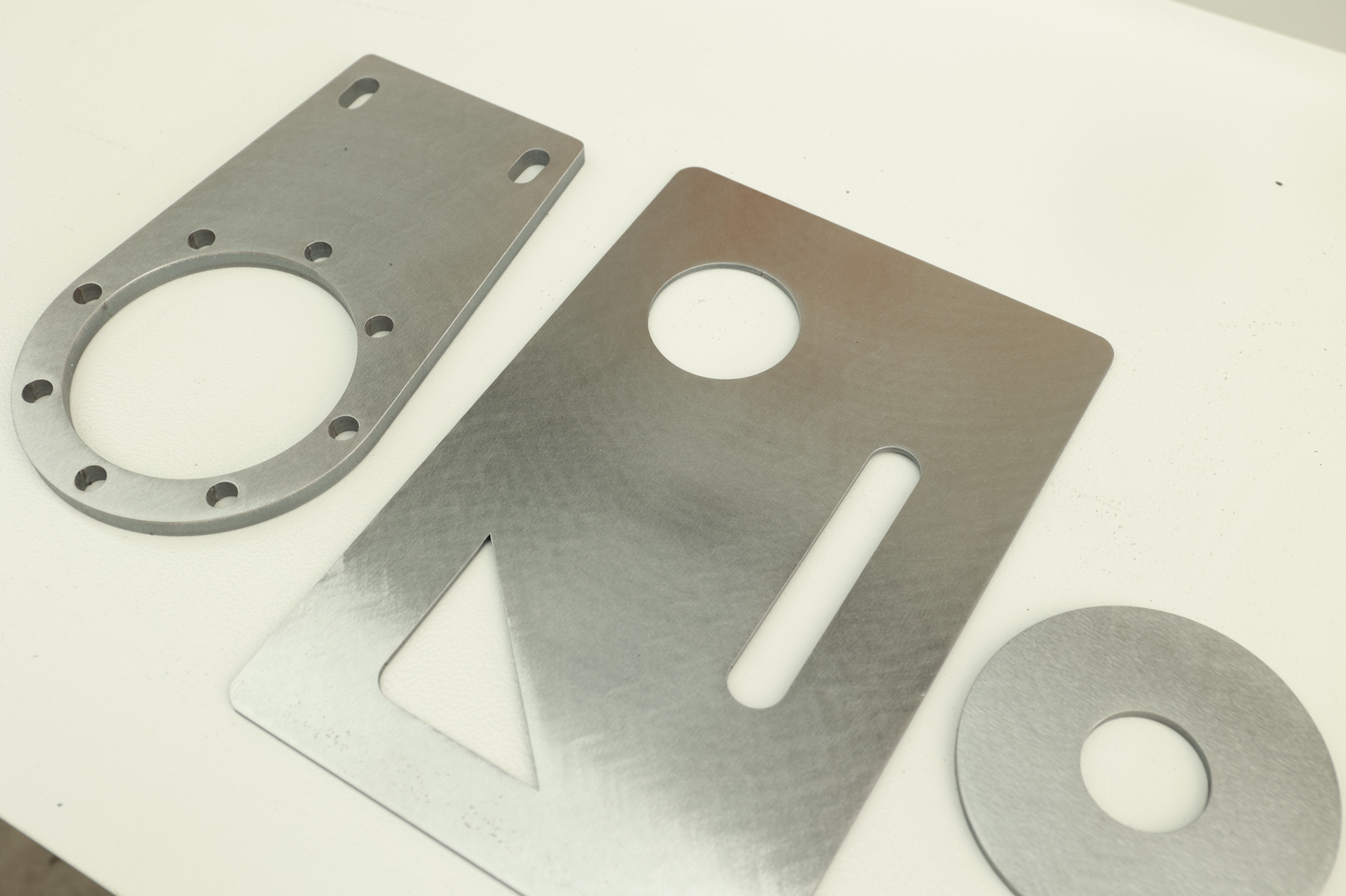

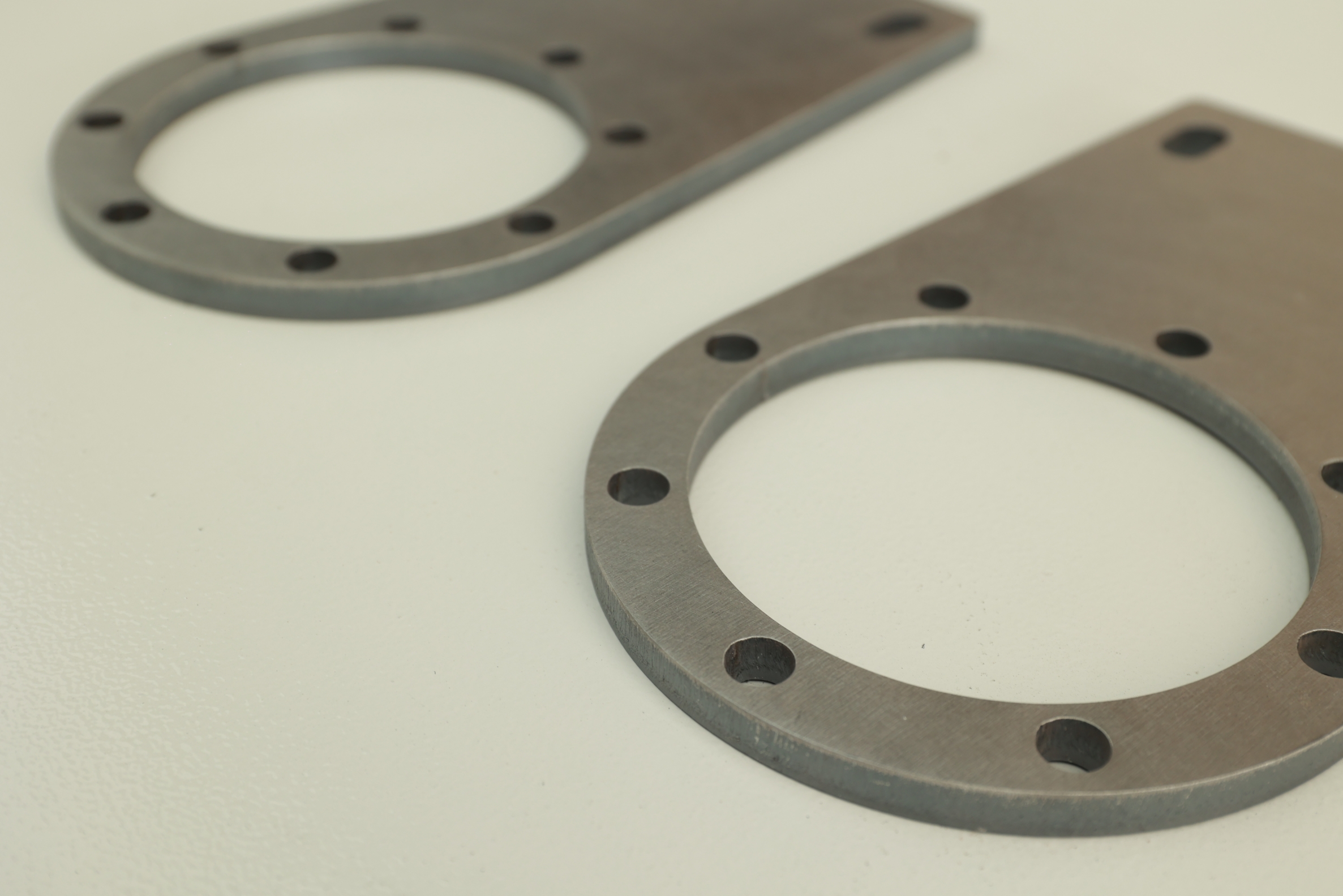

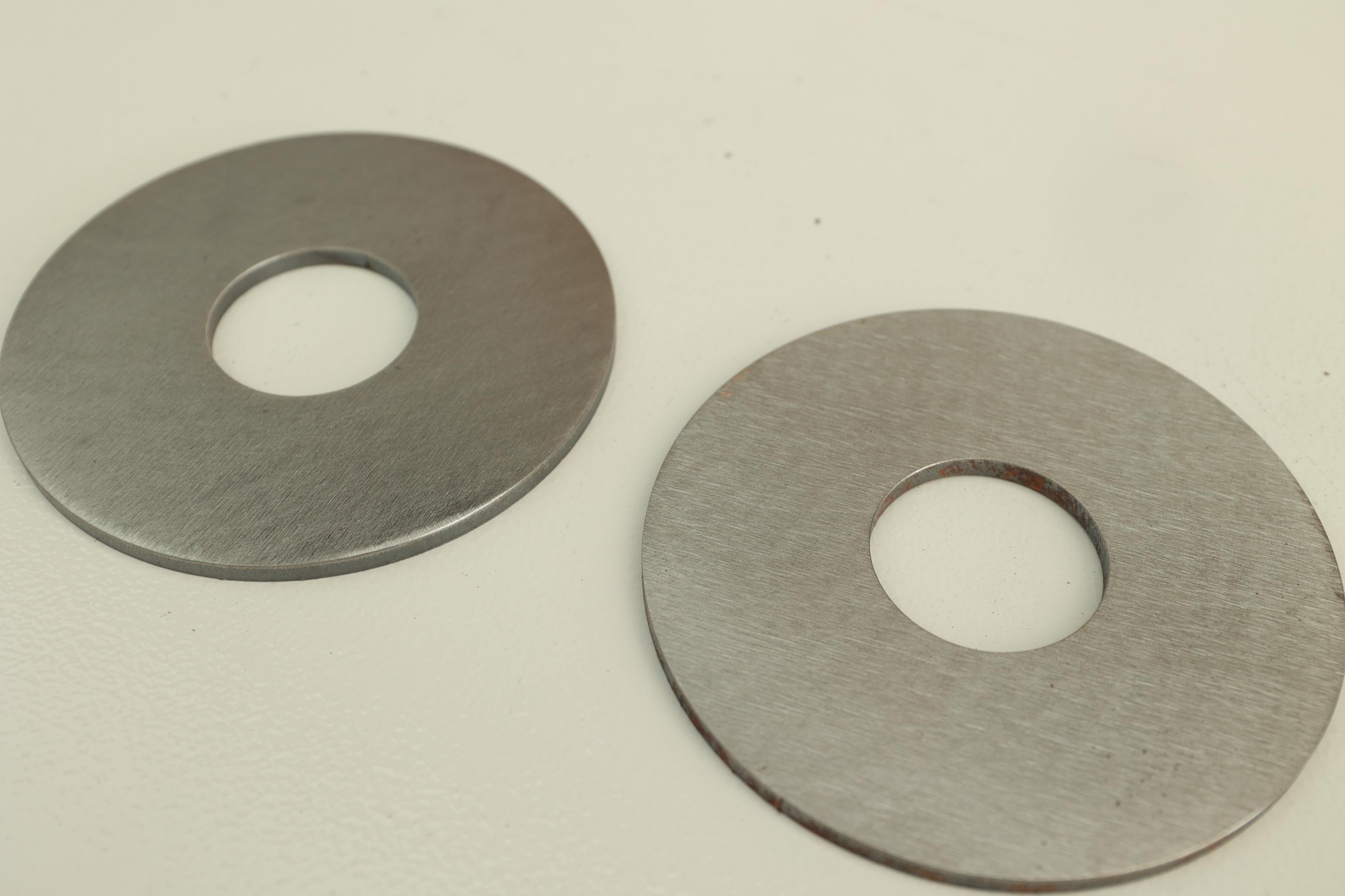

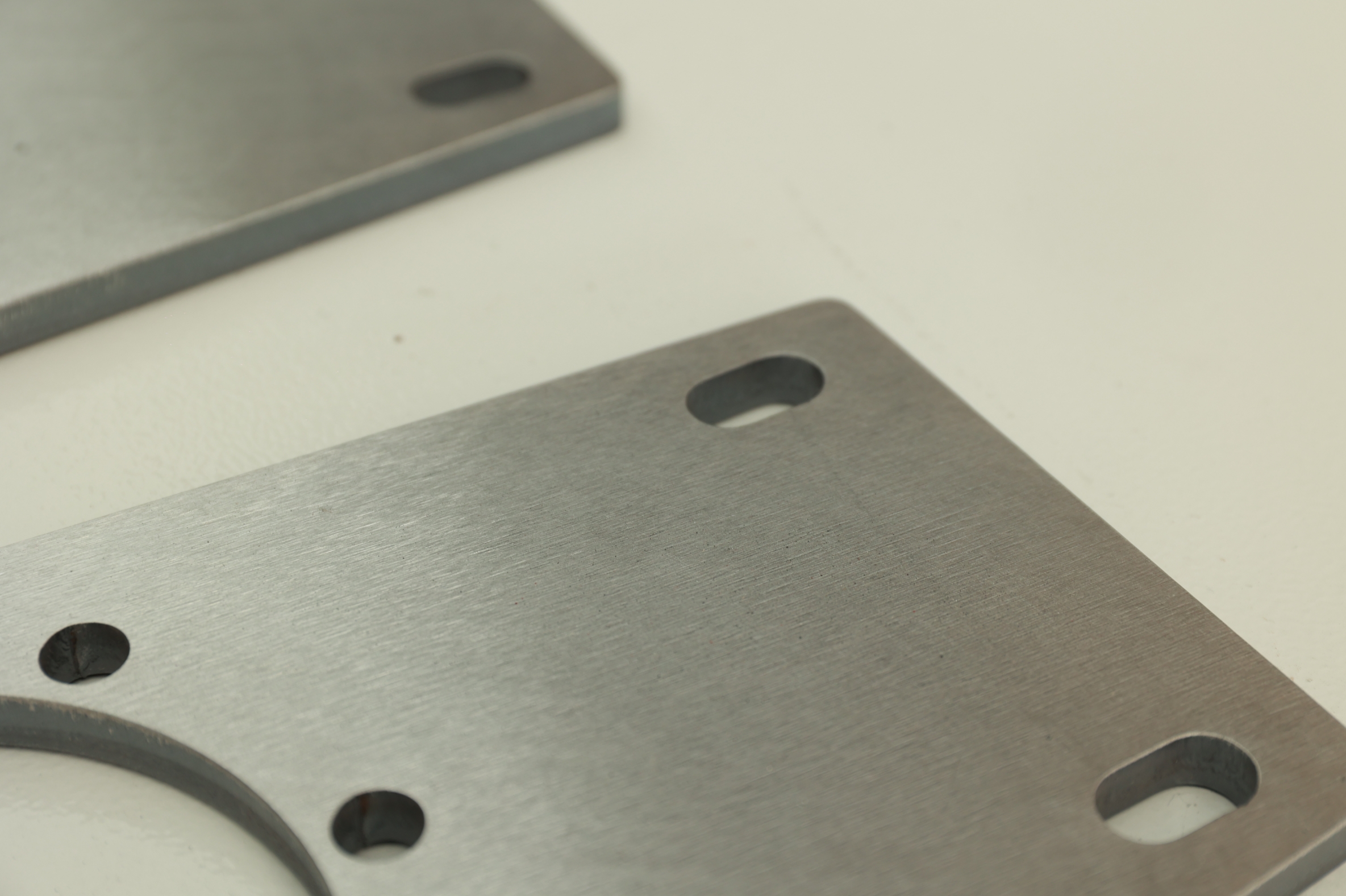

Specifically developed for small sheet metal parts

Safe & efficient processing

Fully automatic adjustable stations

Intuitive multilingual HMI touchscreen

Reproduce with adjustable programs

Integration with ERP & handling systems

Automatic height adjustment of grinding unit

| PARAMETERS | EdgeMaster 300 MINI |

|---|---|

| SR | 300 |

| Conveyor belt speed | 0.5 - 7 m/min |

| Production fixation | magnet system |

| Minimum workpiece dimensions | ≥50 x 50 mm |

| Maximum workpiece width | 300 mm |

| Maximum workpiece height | 0.5-100 mm |

| Belt size | 1650*320 |

| Roller brush size | 300*300*40(1/set) |

| Workbench load-bearing | ≤100kg |

| Machine power supply | 400 V | 50 Hz | 34 A | 11.5 kW |

| Dimensions (L x W x H) | 2150mmX700mm2000mm |

| Weight | 1300kg |